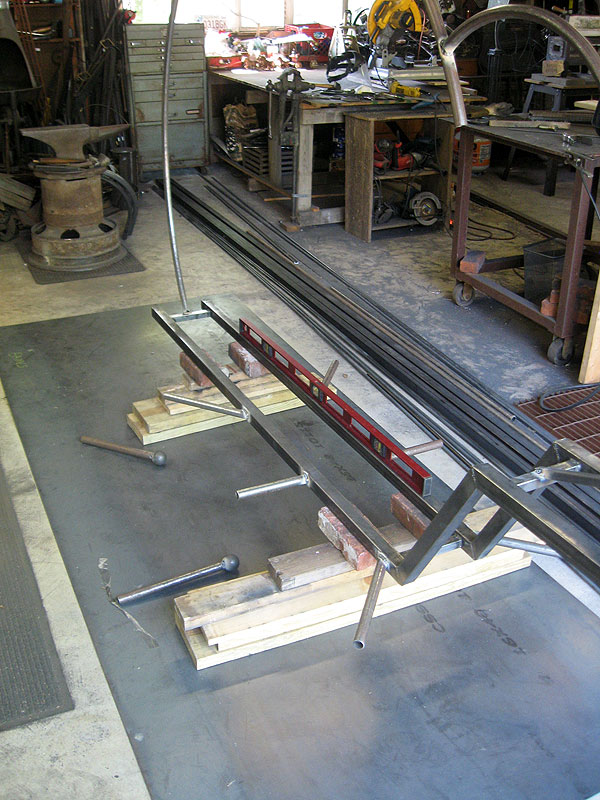

I have really enjoyed making the latest fence and gates to come out of Fossil Forge. This fence project will include two gates and an arbor. The fence sections use 1/2 round steel for the pickets. Each section is 5-feet in length and will be welded to the posts. The photo shows the sections stacked up, ready for the next addition.

Each section will feature three small loops. I made these using a simple jig and some heat. There are two different sizes of the loops.

Here are the sections with the loops in place. These are now ready to travel to the fence site.